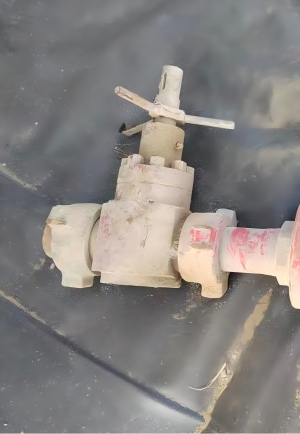

A mud gate valve is a high-pressure valve commonly used in oilfield drilling systems to control the flow of drilling mud(a thick fluid pumped down the drill string during drilling).

A mud gate valve is a gate-type valve specifically designed for abrasive, high-density fluids like drilling mud. It provides a full-bore, straight-through flow path, minimizing pressure drop and turbulence.

Main components

-Body: Heavy-duty steel or alloy housing designed to withstand high pressure(up to 5000-7000psi)

-Gate(wedge): A sliding metal gate that moves up and down to open or close the flow.

-Seat rings: Replaceable sealing surfaces that ensure a tight shutoff.

-Stem: Connects the gate to the handwheel or actuator. Often rising type(the stem moves up and down)

-Bonnet: The top cover of the valve body, housing the stem and packing.

-Handwheel: Manual control for opening and closing the valve

-Packing gland: Prevents fluid leakage around the stem

Applications

-Mud pumps(suction/discharge lines)

-Standpipe manifolds

-Mud tanks and manifolds

-Cementing and fracturing systems

Features

-Full-bore design: allows easy passage of thick drilling fluids and solids.

-Bidirectional sealing: seals in both flow directions

-Replaceable seats and gates: easy maintenance in the field

-Compact and rugged: designed for oilfield harsh environments