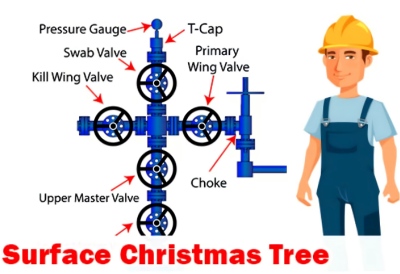

A Christmas tree is an an assembly of valves, spools, chokes, and fittings installed on the wellhead to control the flow of hydrocarbons from an oil & gas well.

It serves as the primary surface pressure-control system once drilling is completed and well has been cased and cemented.

Main functions

Flow control: Regulates production from the well through choke adjustment and valve operation

Shut-in Capability: Enables rapid closure of the well in emergencies or maintenance situations.

Injection access:Provides connection points for gas lift, chemical injection or well simulation.

Pressure monitoring: Houses gauges and ports for monitoring tubing and annulus pressures.

Access for intervention: Allows wireline, coiled tubing, or slickline tools to enter the wellbore via the swab valve.

Typical components

Swab valve: Top valve: allows access for wireline or slickline operations.

Upper master valve: Main shutoff above the production outlet.

Lower master valve: Second barrier below the production outlet, isolates the well.

Wing valve(production wing): Controls flow to the production line.

Kill wing valve: Provides connection for kill fluid or injection.

Choke(fixed or adjustable): Regulates production rate and downstream pressure.

Cross/Body/Spool: Connects all valves, provides structural integrity.

Pressure gauges: Measure tubing and annulus pressures.

Types of Christmas trees

-Surface tree: Mounted on land wells or platform wells above sea level.

-Subsea tree: Installed on the seabed, remotely operated via hydraulic or electric control systems.

Dual-completion tree: Handles two separate production strings from the same wellbore.

Horizontal tree: Common in deepwater wells, the production flow path is horizontal to facilitate subsea connection.